It wouldn’t be too hard to argue that there are a lot of sonic possibilities presented by compressors. Need to distort and smash a source to the point that it’s unrecognizable? Try a compressor. Got a vocal that just needs a little bit more dynamic consistency? Try a compressor. Want to turn down one track every time another track plays? You get the idea.

But what happens when we experiment with routing compressors in different ways? There are the common serial and parallel compression options, which we will cover in this post, but there are more options than just those two choices.

Serial compression is the simplest and most common way of using multiple compressors in conjunction with one another. All you need to do to make use of serial compression is use one compressor as an insert, and then put another compressor on the insert slot after it. Where it gets interesting, though, is how you make those compressors interact with each other.

Serial Compression in Action

One of the most common serial compression techniques is routing your audio through a fast attack, slow release compressor for overall level control. That can then be followed by an aggressive compressor with a medium attack and fast release. Of course, the order of these compressors can be reversed.

If you really want to experiment, you can put an EQ between the two compressors and try boosting different frequency ranges to see how that changes the way the second compressor interacts with the audio!

Parallel compression is the second most common compression routing method. If you don’t already know, parallel compression is the process of compressing a source in a separate track, and then mixing the compressed track with the original track.

Perhaps the most common use case for parallel compression is on drums. To try out parallel compression on drums, get yourself set up with a drum sound that you are happy, or almost happy, with. Make sure all your drum kit pieces are routed to one buss and send that buss to an FX or aux track.

Sending Drums to a Parallel Compression Track

On this new track, pull up a compressor plug-in and dial in some aggressive settings. Don’t be afraid to do large amounts of gain reduction! Once you’ve found settings that you like, turn the track with the compressor all the way down, press play, and slowly blend in the compressor track with the normal drums you started with until you get a blend you like.

Want to take it one step further? Experiment with only sending some drum kit pieces to your parallel compression aux or FX track. For example, some producers prefer only sending their drum shells (kick, snare, and toms) to their parallel compression track so that their cymbals are not affected by the compression. Using drum sample enhancement? Try sending only your samples to the parallel compression track and not your raw drums.

Experimental Compression Routing

Serial compression and parallel compression are the two most common compression routing schemes for one big reason: They are simple!

There are a number of other ways you could try routing compressors into one another. For instance, you could compress a signal in parallel, sum the uncompressed and compressed tracks to a new track, and then use two compressors in series on that new track! You could even stack multiple stages of parallel compression one after the other.

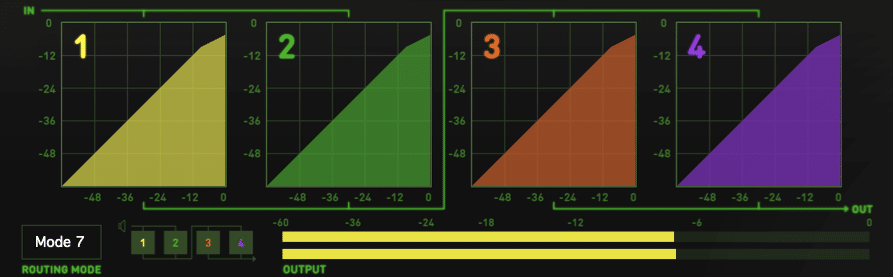

A Unique and Complex Compressor Routing Scheme

However, dealing with all the tracks that come along with compression routing of any kind can get complicated. You could eventually get to a point where there are quite a lot of tracks working in tandem with one another, which means you could end up creating more and more work for yourself. Luckily, though, we’ve got a way for you to simplify this process.

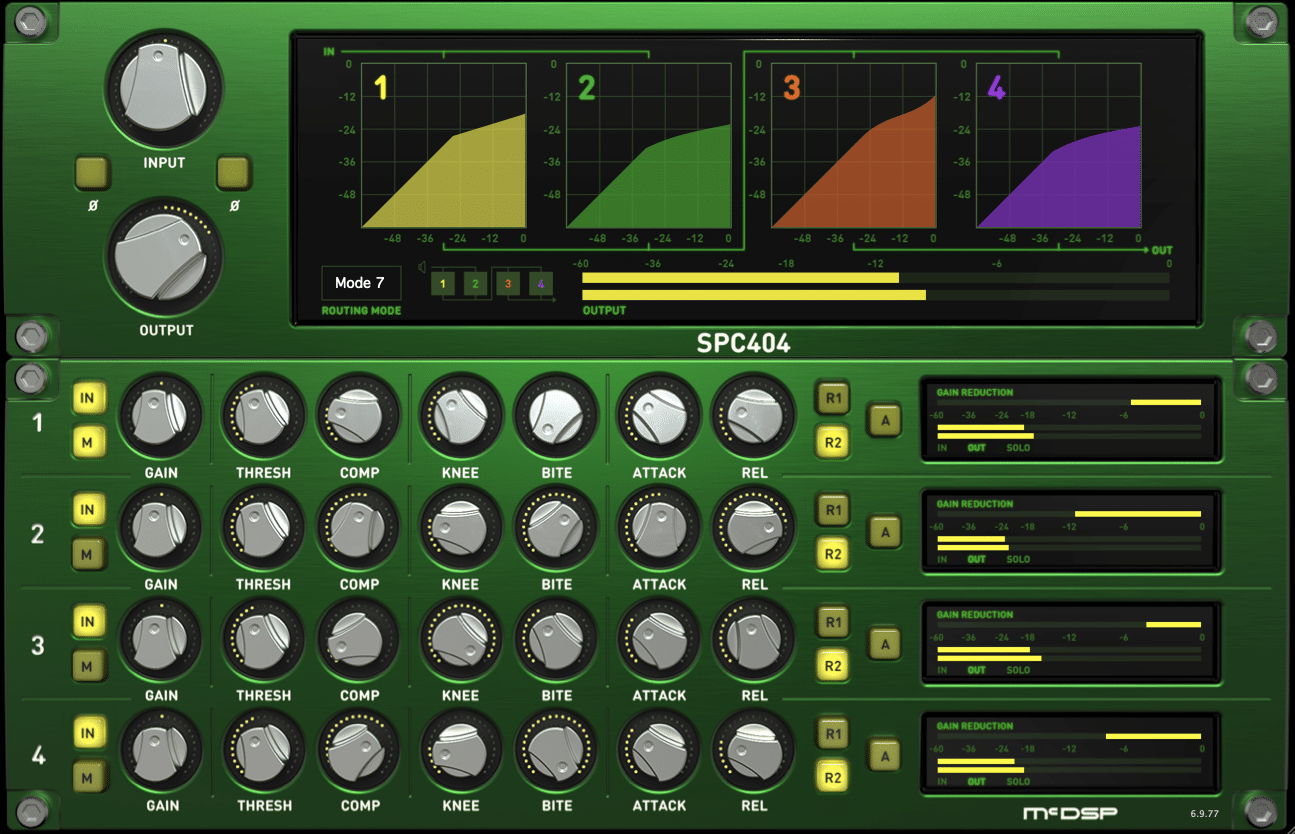

The McDSP SPC2000 Serial/Parallel Compression Plug-In

The McDSP SPC2000 Serial/Parallel Compressor Plug-In

Another great feature included with the SPC2000 Serial/Parallel Compressor plug-in is a master link control that allows you to modify any parameter across all of the SPC2000’s compressors at once! You’ll also get a few different peak detection circuits to choose from, a BITE (Bi-directional Intelligent Transient Enhancement) control for each compressor, and a morphing knee control for each compressor that models various analog compression curves.

As always, we hope you learned something new! Be sure to sign up for our newsletter below to stay up to date on all things McDSP. We’ll see you next time!